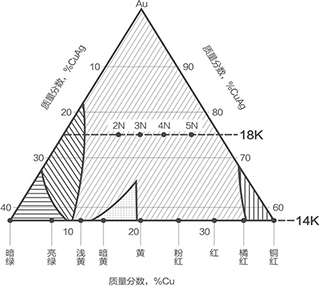

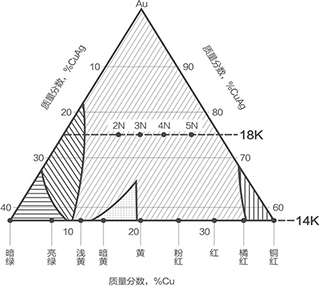

Based on the influence of Ag and Cu on the color of Au, the relationship between the color and composition of Au Ag Cu alloy system is shown in Figure 2, which depends on the different contents of Ag and Cu in the alloy.

Rich Au alloys can exhibit colors such as yellow, red yellow, or green yellow.

For 18K and 14K alloys, the relationship between their color and composition is shown in Figure 1.

The colors 1N, 2N,..., and 5N in the figure are the color standards adopted by Switzerland and Germany, with corresponding colors being light yellow (1N, 2N), yellow (3N), rose red (4N), and red (5N).。

For 14K alloy, with the increase of Cu content, the alloy color gradually changes from dark green to copper red through tender green, light green yellow, dark yellow, yellow, pink, red, and bridge red.

The color of 18K alloy also undergoes a similar change process.

Size of objects | Metal℃ | Flask℃ |

|---|---|---|

| Thin (0.2-0.5mm) | 1110-1150 | 660-720 |

| Medium (0.5-1.2mm) | 1080-1100 | 580-650 |

| Thick (>1.2mm) | 1050-1080 | 500-600 |

The insulation time for solid solution treatment is calculated based on the cross-section, with a 1-inch cross-section insulated for 1 hour.

The insulation time for aging treatment is 1-3 hours, and it is generally recommended to set the upper limit of the insulation time for large cross-section parts to achieve good results.

Choose the upper limit of beryllium content in 275C alloy as much as possible.

This material is in the annealed state and can be directly pulled or cut, allowing for cold working deformation ε Generally, 34-41% is better. When the total deformation is ε When it is greater than 40%, intermediate annealing treatment needs to be added.

The annealing process is as follows: the material after cold processing is kept at room temperature for 10-20 minutes at 700 ℃ -720 ℃, followed by water cooling, polishing to remove oxide skin, and cold processing to form.

If the processing deformation is still greater than 41% after multiple annealing treatments, it is necessary to increase the intermediate annealing treatment.

Recovery of elasticity treatment: 30-40% of cold working deformation before recovery of elasticity treatment. The process is to keep the material at 400 ℃ for 8-10 minutes after cold processing, and then air cool it out of the furnace.